Parameter Setting

What is parameter setting?

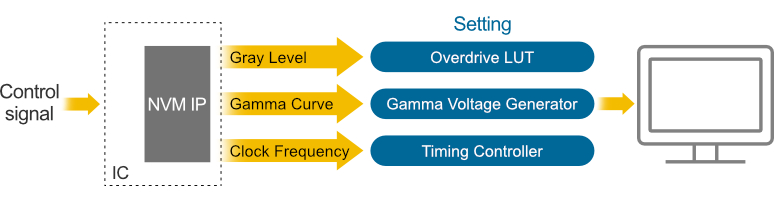

After wafer fabrication, all key application parameter of the device are stored in NVM for system function configuration and calibration.

During and after system assembly, certain parameters of the ICs may have to be configured and stored so that they can work efficiently with other system components. By adjusting the parameters, designers can calibrate performance discrepancies to match system specifications.

Driver ICs typically require NVM to store device parameters. For example, gray levels and gamma curves are stored in display driver ICs for image quality optimization. More complex systems may require real-time recording of system parameters (i.e. battery impedance) in order to improve product life (i.e. laptop battery packs).

eMemory’s Logic NVM Silicon IP Benefits and Features

eMemory’s logic NVM silicon IPs enable configurability during and after system assembly. Other benefits include:

Testable at the Circuit Probe (CP) stage; thus, avoiding yield loss at Final Test (FT), Module, and System stages.

Optimized for various applications and densities.

Support logic, mixed-signal, RF, high-voltage, BCD, SiGe, automotive, and low-power processes.

Silicon-proven at 23 major foundries and available in over 300 qualified processes.

Applications

Key Storage

Applications

Function selection

Applications